| POWERPOINT |

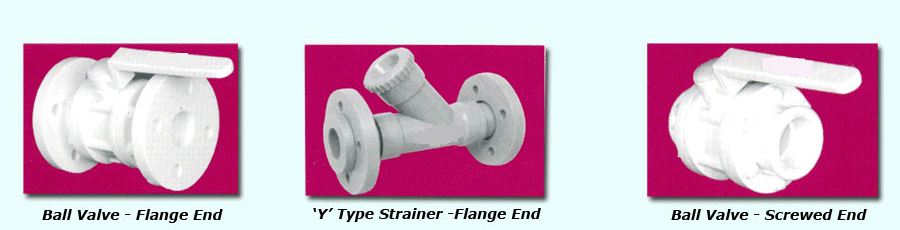

| VALVES |

| Size | Flange Diameter 'D' | Flange Thickness 'T' | Face To Face 'L' | No. of Holes 'G' | No. | Part | Material | |

| 1" | 120mm | 18mm | 150mm | As per | 1 | Body | Polypropylene | |

| 1½" | 140mm | 20mm | 172mm | Requirements | 2 | Ball | Polypropylene | |

| 2" | 168mm | 22mm | 200mm | Tolerance±3mm | 3 | Seal Ring | Teflon | |

| 2½" | 185mm | 25mm | 235mm | 4 | Packing ring | Neoprene | ||

| 3" | 200mm | 25mm | 250mm | 5 | Steam Seal Ring | Teflon | ||

| 4" | 230mm | 28mm | 300mm | 6 | 'O' Ring | Neoprene | ||

| 6" | 300mm | 32mm | 460mm | 7 | Stem | M.S.with p.p.coating. | ||

| 8 | Handle | M.S.with p.p.coating. | ||||||

| 9 | Stude | M.S. Zinc Plated | ||||||

| 10 | Hexnut Washer | M.S. Zinc Plated |

| Size | L±3 | OD | T |

| 25mm | 136 | 118 | 17 |

| 40mm | 166 | 141 | 18 |

| 50mm | 177 | 160 | 21 |

| 65mm | 255 | 183 | 25 |

| 80mm | 255 | 200 | 25 |

| All Dimension are in mm. | |||

| No. | Part | Material |

| 1 | Body | Polypropylene |

| 2 | Solid Ball | Polypropylene |

| 3 | Seat PAD | Polypropylene |

| 4 | Seat | Neoprene/EPDM/VITOM/PTFE |

| 5 | Stop Ring | Polypropylene |

| Size | L ± 3 | OD | T |

| 25mm | 140 | 120 | 16 |

| 40mm | 197 | 140 | 17 |

| 50mm | 210 | 163 | 19 |

| 65mm | 290 | 183 | 23 |

| 80mm | 290 | 200 | 23 |

| All Dimension are in mm | |||

| No. | Part | Material |

| 1 | Body | Polypropylene |

| 2 | Solid Ball | Polypropylene |

| 3 | Seat Pad | Polypropylene |

| 4 | Seat | Neoprene/EPDM/VITON/PTFE |

| 5 | Nut | Polypropylene |

| 6 | Stainer | Polypropylene |

| 7 | Stop Ring | Polypropylene |

| Size | Flange Diameter 'D' | Flange Thickness 'T' | Face To Face 'L' | No of Holes 'G' | Glass Length |

| 1" | 120mm | 18mm | 185mm | As Per | 3" |

| 1½" | 140mm | 20mm | 190mm | Req.Tolerance± | 3" |

| 2" | 168mm | 21mm | 205mm | 3mm | 3" |

| 2½" | 185mm | 25mm | 250mm | 4" | |

| 3" | 200mm | 25mm | 250mm | 4" | |

| 4" | 230mm | 28mm | 270mm | 4" |

| No. | Description | Material | Qty. |

| 1. | Side Piece/Connector | P.P. | 2 |

| 2. | Glass Tube | Glass (Borosil) | 1 |

| 3. | Stud | M.s. | Req. |

| 4. | Nut & Washer | M.S. | Req. |

| 5. | Stud Tube | P.P. Tube | Req. |

| 6. | Crisent Ring | PTFE | 2 |

Industries Where Used |

Technical Data |

|||||||||||||||||||||||||

|

Powerpoint Ball valves are available in range from 1" to 6". All part of valve are made from P.P. and P.T.F.E. protective from corrosive Chemicals. Ball valves are easy opening and closing by quarter turn. Main load carrying part like stem, handle are inserted with metal insert ensuring strength and long service life. Valves are totally corrosion resistant externally and internally. Since, all metallic parts like handle, stem, nuts etc. are fully covered by moulded polypropylene and also caps of polypropylene. |

| Testing |

| Every Ball Valve undergoes pressure testing of body and seat hydrotest of 10 Kg/cm². can be used to 80°C temp. |